EPDM Single-Ply Roof Membrane

In the early 70's, a highly successful single ply roof membrane hit the roofing market and BUR met some high tech competition. Its name is EPDM or more commonly called a rubber roof. EPDM is a rubber membrane whose principal components consist of Ethylene and Propylene.

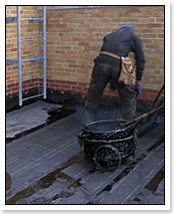

A flexible rubber matrix forms when a small amount of Diene is added to the mix. At first EPDM membranes were used as pond liners, but it didn't take long before the roofing industry saw its value and created a high tech, high quality roof membrane. American Roofing has installed hundreds of acres of EPDM roof membranes from fully adhered, mechanically attached to ballasted (loose rock) EPDM roof systems. The principle advantages to EPDM are that it is lightweight, unaffected by standing water and surpass the test of time for superior longevity. There is also very little odor and mess, which is appealing to building owners and occupants.

In the late 90’s, a new rubber product called TPO or Thermaplastic Olefin was perfected, giving all the single ply rubber benefits listed above and carried a white colored membrane, giving the extra benefit to occupants of reduced cooling cost in the hot summer months.

In particular, American Roofing prefers Firestone roofing EPDM, insulation and fasteners because of their diligent and continual research in the application and durability of their products. They offer a single source responsible product system that carries an interrelated warranty.